How Can Households Install a Solar PV System? Installation Steps and Budget Explained

Orientation and Outline: Why Home Solar, What to Expect, and How This Guide Flows

Installing a solar PV system at home blends practicality with a touch of quiet awe: you are turning sunlight into electricity that runs your kettle, your computer, and your evening lights. Beyond the feel‑good factor, rooftop PV can help stabilize household spending by offsetting utility bills, reduce exposure to rising tariffs, and cut local emissions. This guide is written to be both comprehensive and approachable, so you can map a plan that fits your roof, your budget, and your comfort with tools.

Before we dive into the nuts and bolts, here is the outline of what you will learn and do, presented as a clear path from idea to switch‑on:

– Define goals, check your roof, and gather energy bills

– Size the system based on usage, sun hours, and available space

– Choose hardware: modules, inverters, mounting, optional batteries

– Secure permits and utility approvals

– Install racking, wire safely, commission, and monitor performance

– Understand costs, financing, savings, and ongoing maintenance

Home solar is not one‑size‑fits‑all. A compact 3 to 5 kW array may be perfect for a small household with efficient appliances, while a larger 8 to 12 kW setup can better match a family with electric heating or a plug‑in vehicle. Typical residential arrays add roughly 2 to 6 pounds per square foot of distributed weight to a roof, a load many structures can support when properly anchored; still, a structural check is wise, particularly on older homes or if you plan to adjust roof pitch or add heavy snow guards.

Some households prefer professional installation for speed, code compliance, and warranty coverage. Others enjoy a supervised DIY route, hiring a licensed electrician for the interconnection while handling layout and mounting. Either approach can work when safety and local regulations are prioritized. Expect the administrative journey—designs, permits, and utility approval—to take longer than the physical build. The latter is often a one‑ to three‑day effort; the former can run several weeks depending on jurisdiction. With that framing, the next sections translate the outline into detailed, practical steps you can follow.

Planning and Design: Site Assessment, Load Analysis, and System Sizing

Great solar projects begin at the desk. Start by collecting 12 months of electricity bills to capture seasonal swings. Note monthly kWh and the cost per kWh, including any time‑of‑use windows. If you do not have a full year of data, estimate consumption from appliance nameplates and typical run hours, then add a margin for future changes such as electrified heating or a new vehicle. Set a target offset—many households aim for 60 to 100 percent of annual usage—keeping in mind your roof’s size, shading, and local rules on export and interconnection.

Next, assess your roof. Ideal orientation in the northern hemisphere is generally toward the south, though east‑ and west‑facing arrays can perform well and may better align with morning or afternoon usage. A tilt near your latitude can improve annual yield, but flush‑mounted systems at common roof pitches are widely used and often preferred for simplicity. Watch for shade from chimneys, trees, or nearby buildings; even partial shade can cut output on a string. As a rule of thumb, aim for little to no shading between mid‑morning and mid‑afternoon, when irradiance is strongest.

Estimate production using reputable solar irradiance datasets or calculators provided by national labs and meteorological agencies. In sunny climates, 1 kW of PV may produce roughly 1,300 to 1,700 kWh per year; in cloudier regions, 900 to 1,100 kWh is common. Multiply your target system size by local yield to gauge annual production and compare it to your kWh offset goal. Then translate energy into roof area: high‑efficiency residential modules often deliver 180 to 220 watts per square meter of panel footprint, with typical panels around 1.7 to 2.2 square meters each.

Do a quick structural and electrical pre‑check. Roof framing should be sound, and anchoring should land on rafters or trusses using flashed penetrations or compatible clamps on metal profiles. On the electrical side, note your main service size (commonly 100 to 200 amps) and available breaker positions. Some jurisdictions allow certain back‑feed configurations that sum up to a percentage above busbar rating; others require line‑side taps or service upgrades. An early conversation with a licensed electrician can prevent redesigns later.

Summarize your design brief in a short document for permitting and quotes: target kW, module count, layout sketch, inverter type, interconnection method, and any battery plans. This brief becomes the thread that ties together hardware choices, cost estimates, and approval paperwork, streamlining every step that follows.

Hardware Choices and Layout: Modules, Inverters, Mounting, and Batteries

Picking components is where your plan gets real. Most households choose crystalline‑silicon modules, which offer dependable performance and compact footprints. Monocrystalline options tend to deliver higher efficiency per square meter, allowing more power on a small roof. Modules with half‑cut cells can improve shade tolerance and reduce resistive losses. Thin‑film has niche uses on certain surfaces but typically requires more area. Pay attention to warranted degradation: many panels guarantee around 80 to 88 percent of nameplate power after 25 years, indicating long service life under normal conditions.

Inverters are the brain and translator of your system. Three common approaches dominate residential rooftops:

– String inverter: Efficient, streamlined, and cost‑effective; best on unshaded roofs with uniform orientation

– String inverter with module‑level power electronics: Adds optimizers to mitigate shade and enable module‑level monitoring

– Microinverters: Each panel has its own inverter for granular monitoring and shade resilience, with simplified DC wiring

Trade‑offs include upfront cost, efficiency, points of failure, and maintenance logistics. Microinverters provide strong partial‑shade performance and straightforward expansion but may cost more per watt. A string inverter concentrates electronics in one location and is often simpler to replace after many years, though a single point of failure affects the whole array until addressed. If your roof has multiple orientations or persistent shade patches, module‑level control is attractive.

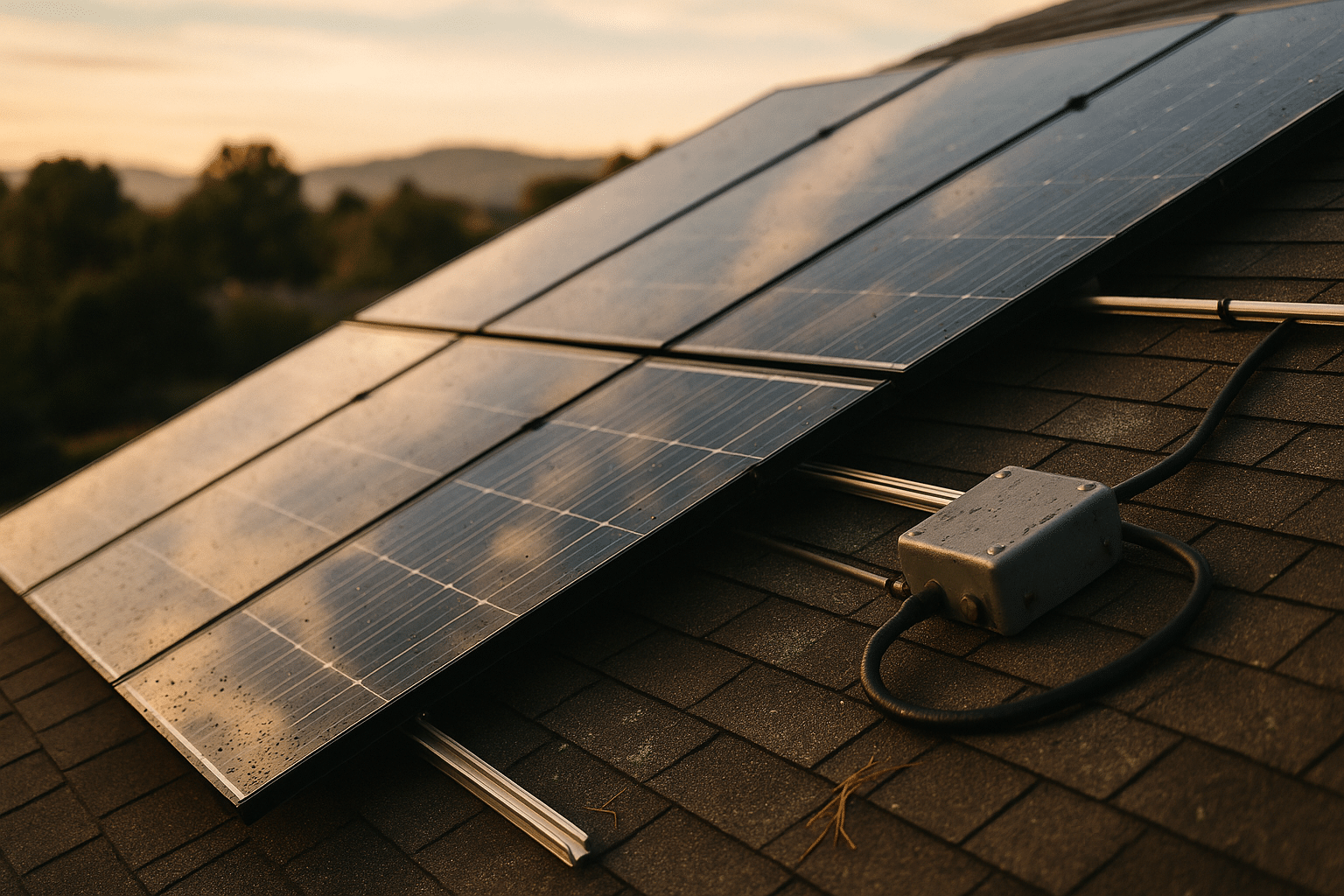

Mounting choices hinge on roof type. Composite shingle roofs often use flashed L‑feet anchored into rafters; tile roofs need standoffs or replacement hooks that maintain waterproofing; metal standing‑seam roofs can use clamp systems that avoid penetrations. Include wind and snow loads in your design and follow manufacturer torque specs. Thoughtful wire management—UV‑resistant clips, smooth conduit runs, appropriate bend radii—reduces maintenance and preserves aesthetics. Leave required fire setbacks along ridges and hips, and keep clear paths for safe roof access.

Optional storage changes how your solar behaves. Lithium‑iron phosphate batteries are widely favored for stability and long cycle life. Storage can provide outage backup and help shift solar energy into evening peaks under time‑of‑use pricing. Sizing typically ranges from 5 to 20 kWh for households, depending on critical loads and desired backup hours. Some utilities require additional protective relays or smart meters when batteries are present. Consider also a critter guard around the array to deter nesting and protect wiring, and include surge protection and properly rated disconnects to safeguard your investment.

Permits, Paperwork, and Installation Steps: From Application to Commissioning

Paperwork may not sparkle like new panels, but it is the backbone of a safe, legal, grid‑connected system. You will likely need a building permit (structural), an electrical permit, and utility interconnection approval. In some areas, fire department review or historic district consent is part of the process. Your application packet usually includes a site plan, an array layout, a single‑line electrical diagram, product datasheets, and structural notes. Many jurisdictions offer standard checklists; aligning your submittal to those lists speeds approval.

Utility interconnection steps vary. Common elements include an online application, proof of liability coverage, equipment specifications, and a proposed metering arrangement. Where export is allowed, you may be placed on a netting or buy‑back tariff; elsewhere, self‑consumption rules or export limits can apply. Clarify whether you will need a meter swap, a service upgrade, or a dedicated generation meter. Typical timelines run two to eight weeks, though some offices move faster and others slower depending on workload.

Once authorized to build, the physical installation follows a methodical sequence:

– Lay out rails and mark rafter locations; drill pilot holes and set lag bolts with flashing for waterproofing

– Level and torque racking; place mid‑ and end‑clamps per spec, maintaining required roof setbacks

– Mount the inverter(s) on a cool, accessible, shaded wall; install DC/AC disconnects and surge protection

– Pull conductors in listed conduit; size wire for voltage drop and ampacity; bond racking and enclosures

– Set the modules, dress cables, make connectors with correct polarity; test open‑circuit voltage per string

– Land the AC into a dedicated breaker or a line‑side tap; label equipment and pathways as required

Commissioning is equal parts caution and celebration. Verify mechanical attachments, torque, and roof sealing. Check continuity, insulation resistance, and grounding. Confirm inverter settings match grid requirements (voltage, frequency windows, anti‑islanding). Power up according to the prescribed order: usually AC first, then DC. Configure monitoring to track daily production and detect anomalies. After building and electrical inspections pass, the utility issues permission to operate. From first sunrise, you can watch the production curve rise like a tide across your dashboard.

Safety remains non‑negotiable: use fall protection, avoid live work, de‑energize circuits whenever possible, and follow local code language for rapid shutdown, working clearances, and labeling. When in doubt, bring in a licensed electrician to review or complete the interconnection.

Budget, Financing, and ROI: Line‑Item Costs, Savings, and Sensible Expectations

Solar budgets are shaped by location, roof complexity, component choices, and labor markets. A practical way to think about cost is dollars (or local currency) per watt of DC capacity. As a broad reference, many residential projects land around 2.0 to 4.0 per watt before incentives in higher‑cost markets, and can be lower where permitting is streamlined and soft costs are trimmed. Hardware alone (modules, inverter, racking, wiring, and balance‑of‑system parts) often accounts for 40 to 60 percent of the total, with the rest tied to design, permits, labor, and overhead.

Here is how a typical 6 kW roof‑mounted system might break down, expressed as flexible ranges rather than promises:

– Modules: 1.0 to 1.5 per watt, depending on efficiency and warranty terms

– Inverter(s) and rapid‑shutdown gear: 0.4 to 0.8 per watt, varying by architecture

– Racking and roof attachments: 0.2 to 0.5 per watt, influenced by roof type and wind/snow loads

– Electrical balance of system (wire, conduit, disconnects, breakers, labels): 0.2 to 0.4 per watt

– Design, permits, inspections, and administrative time: 0.1 to 0.3 per watt

– Labor and overhead: 0.5 to 1.0 per watt

That places a representative pre‑incentive subtotal for 6 kW at roughly 12,000 to 24,000 in many markets. Storage adds a separate budget line: a 10 kWh battery system commonly ranges from 8,000 to 15,000 before incentives and may require additional protective devices or an upgraded inverter. Roof work such as replacing worn shingles or adding structural reinforcement is outside the solar budget but smart to combine with the installation to avoid rework.

To estimate savings and payback, pair your expected annual production with your tariff structure. Suppose a 6 kW array yields 7,800 kWh per year and your blended rate is 0.22 per kWh; gross bill offset would be about 1,716 annually before fixed charges and policy details. Under time‑of‑use plans, west‑facing arrays and storage can shift value into late afternoon peaks. Incentives, where available, reduce upfront cost; always confirm eligibility rules and caps, as programs evolve.

Financing options include cash purchase, secured or unsecured loans, and structured agreements where a third party owns the system. Cash typically delivers the lowest lifetime cost. Loans spread payments and can be sized so monthly outlay approximates bill savings. Third‑party ownership can lower upfront cost but shifts some benefits; read performance and escalation terms carefully. Whatever path you choose, include a 5 to 10 percent contingency for surprises, plan for inverter replacement around years 10 to 15 in some architectures, and budget a modest annual amount for maintenance and monitoring. With realistic expectations and a clean design, the numbers often pencil out, and the system quietly pays its way in the background.